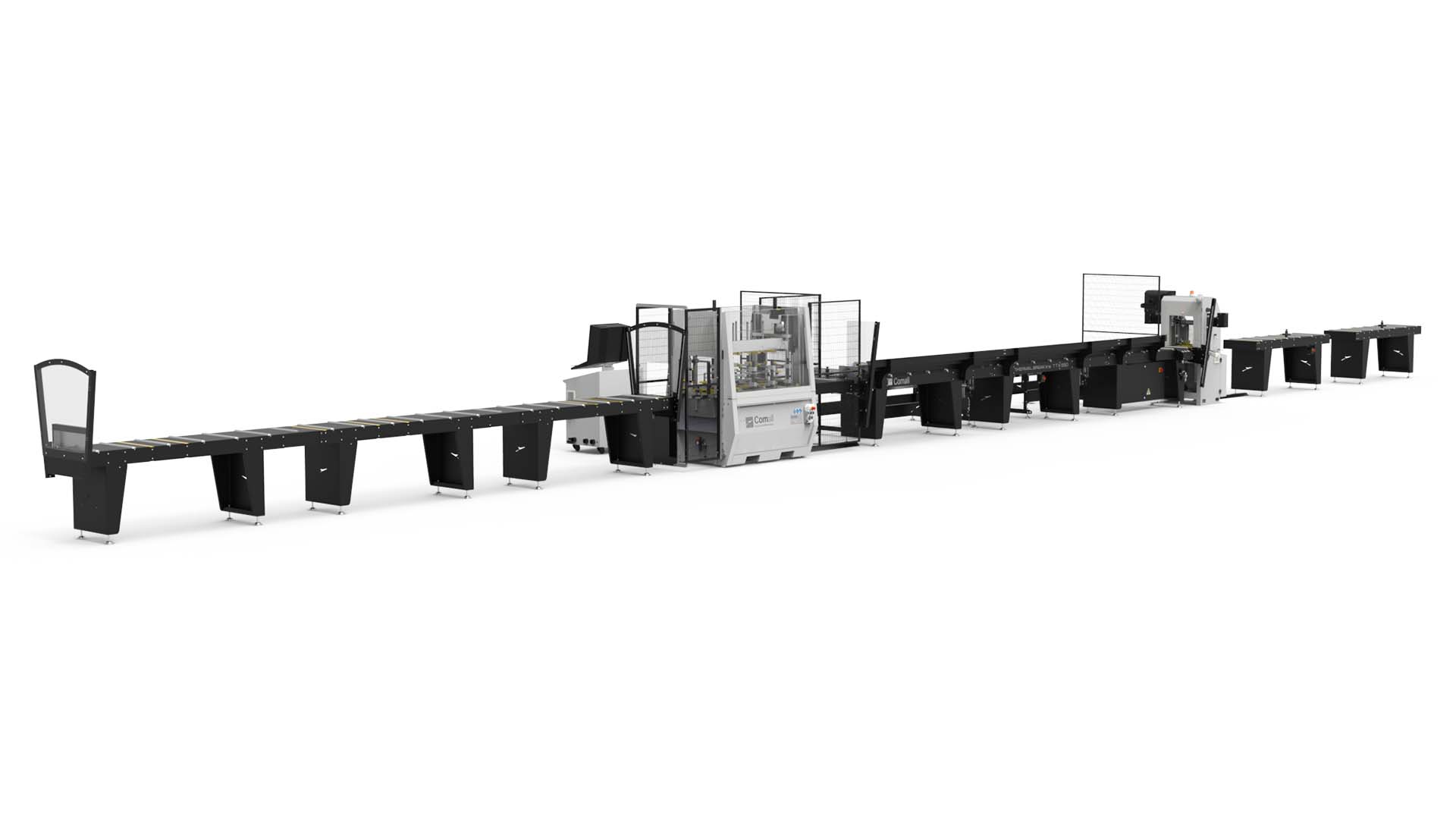

TTK 550

TTK 550 Assembly Line for Thermal Break Aluminium Profiles

Compact Efficiency for the Production of Insulating Aluminium Profiles

The TTK 550 is an automated line designed for assembling thermal break aluminium profiles, ideal for small to medium-scale production. Thanks to its compact, modular configuration, it optimises space and resources while maintaining high precision and repeatability. It can achieve a productivity of 40–50 bars/hour.

MAIN ADVANTAGES

- Up to 50 bars/hour productivity

- Reduced human errors and cycle times

- Quick setup with programmable memory

- Integration with traceability systems

- Centralised control via TTK Integra software

LINE COMPONENTS

- Loading conveyors – precise bar guidance towards knurling

- CNC knurling machine – dual station for knurling and polyamide insertion

- Knurling discharge unit – safe and orderly profile handling

- Controlled-pressure assembler – even fixing with pressing discs

- Discharge conveyor – automatic transfer of the assembled profile

- Final testing – pull-out resistance test for quality validation

SMART AUTOMATION

- The automatic version of the TTK 550 includes:

- CNC knurling and assembling machines

- TTK Integra software for full process management

- Optional modules:

- TTK Office for remote programming

- TTK Statistic 4.0 for performance analysis

IDEAL FOR

- Companies with frequent design changes

- Production units looking to increase efficiency

- Businesses seeking a compact yet complete system

Thermal break

The Comall thermal break range includes complete systems for the in-line production of thermal break profiles, knurling machines, assemblers and machines for the final testing of profiles.

Fom Industrie’s consolidated and highly valued thirty-year industrial project has provided a unique starting-point for the creation of this full range of machines for thermal break assembly.